下载文件

Life Cycle Assessment (LCA) and Carbon footprint of ELIX products

请您填写以下空格,您的邮件会收到下载链接

Climate change is a global challenge we must face: adaptation and mitigation are two sides of the same coin which we incorporate into our sustainability strategy.

Our "Caring about climate" project represents a step forward in our commitment to the protection of the environment and the reduction of our environmental footprint, as well as an opportunity for us to adapt to climate-related risks.

CARING ABOUT CLIMATE

PROGRAMME OBJECTIVES

ACTION PLANS:

REDUCING OUR ENVIRONMENTAL FOOTPRINT

We have policies which define our commitment to environmental protection:

CERTIFICACIONES:

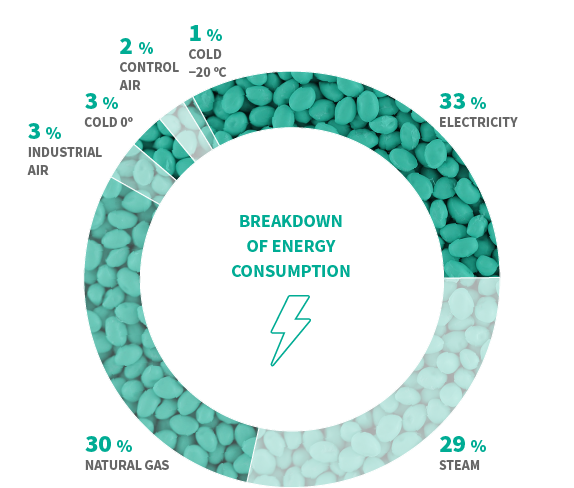

Reducing our environmental footprint means improving our energy performance and reducing our waste generation and water consumption.

Energy Efficiency Programme

Significant Environmental Aspects Programme

Project for minimising wastewater with high levels of TOC (total organic carbon)

Our plan is to reduce our environmental footprint by exploiting our energy efficiency and waste management programmes already in place, and adopting renewable energy and carbon compensation technologies.

WE ARE CONTINUING OUR ZERO PELLET LOSS PROGRAMME

ELIX forms part of a value chain of microplastics in the form of resin pellets and plastic powder. Though ELIX is not the direct cause of plastics being present in the sea, it does form part of the plastic life cycle, and therefore commits to being part of the solution.

To help face this global problem, it is important to act locally. Our Zero Pellet Loss Programme, which began in 2017 with the international programme Operation Clean Sweep (OCS), flakes and powder, and avoid the deposit of these materials into rivers and oceans, formalising our commitment to achieve SDG 14 for the protection of sea life.

At the same time, during 2021, we have carried out the following improvement measures:

Energy efficiency

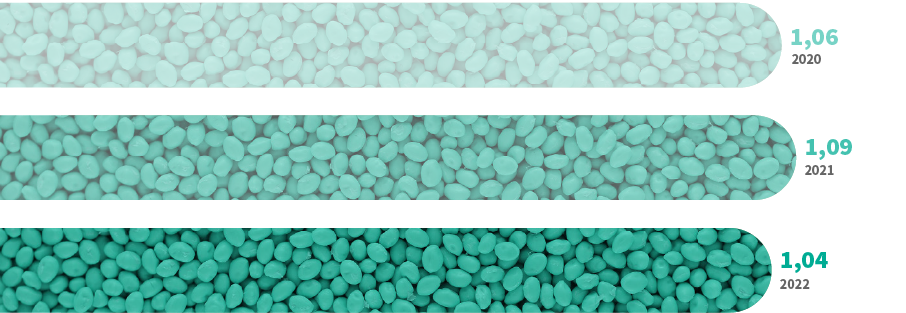

We reached all of our specific reduction goals, in this way improving our energy performance

textos.2022_enviroment_40_1

textos.2022_enviroment_40_7

textos.2022_enviroment_40_8

textos.2022_enviroment_40_9

textos.2022_enviroment_40_11

textos.2022_enviroment_40_12

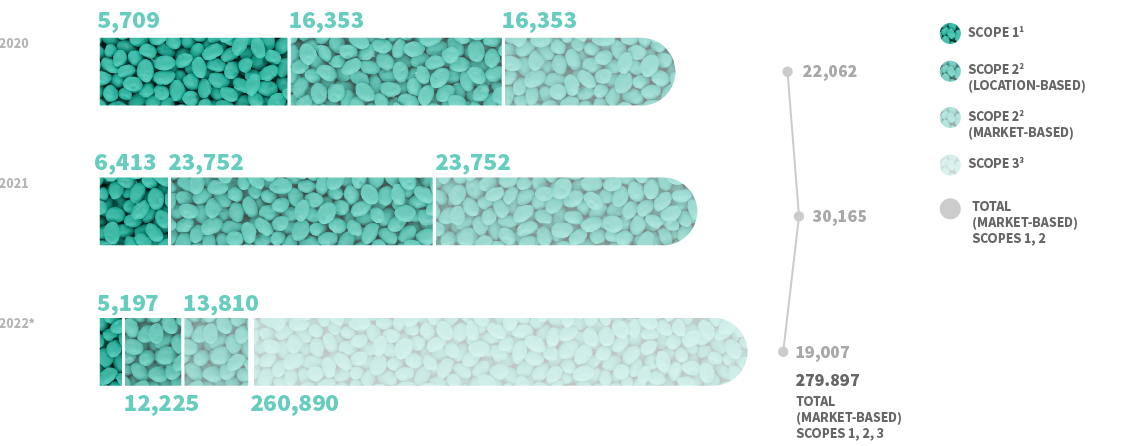

The carbon footprint of our organization

Calculating our carbon footprint provides us with useful information for identifying those aspects of our activity that have the greatest environmental impact, and helps us to focus our efforts on reducing it.

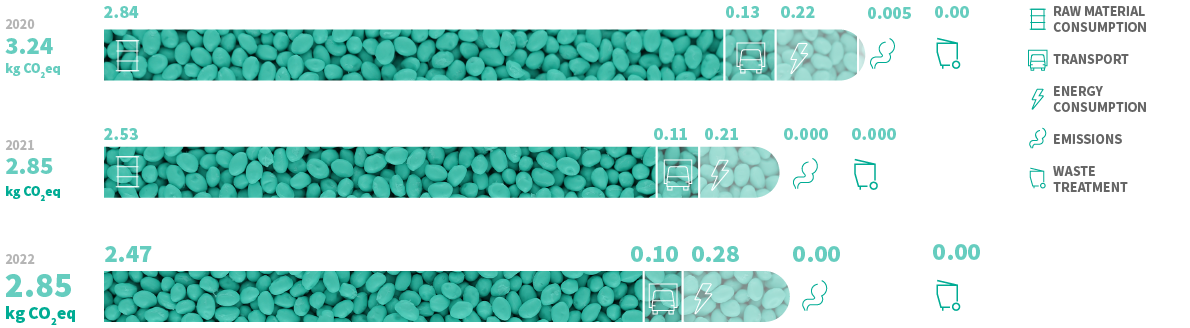

This year, we calculated the carbon footprint for our products by performing a Life Cycle Assessment (LCA) based on the ISO 14040 and ISO 14044 standards, which includes the impact from the extraction of the raw materials through to the transportation to our customers. When making this calculation, we took the three types of scope into account: scope 1 (direct emissions) and scopes 2 and 3 (indirect emissions).

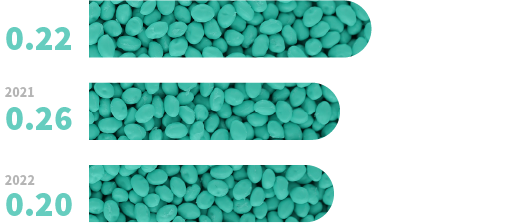

The carbon footprint of our product is calculated from the Life Cycle Analysis (LCA) of the scope, called "from the cradle to the door", which has taken into account from the extraction and processing of raw materials until the product is packaged for final distribution. The main A novelty with respect to the calculation of previous years is that it has been possible to incorporate the carbon footprint values of our suppliers of the main raw materials

textos.2022_enviroment_04

textos.2022_enviroment_05

textos.2022_enviroment_06

textos.2022_enviroment_07

textos.2022_enviroment_09

textos.2022_enviroment_010

VOLUNTARY AGREEMENTS FOR REDUCING GHGs

As a member company of the Voluntary Agreement for the Reduction of Greenhouse Gas (GHG) Emissions programme of the Catalan government’s Climate Change Office, we presented our updated emissions inventory along with a proposal for new actions and information on our improvement measures already in place.

textos.2022_enviroment_2

textos.2022_enviroment_3

textos.2022_enviroment_4

textos.2022_enviroment_5

textos.2022_enviroment_6

textos.2022_enviroment_7

Other emissions

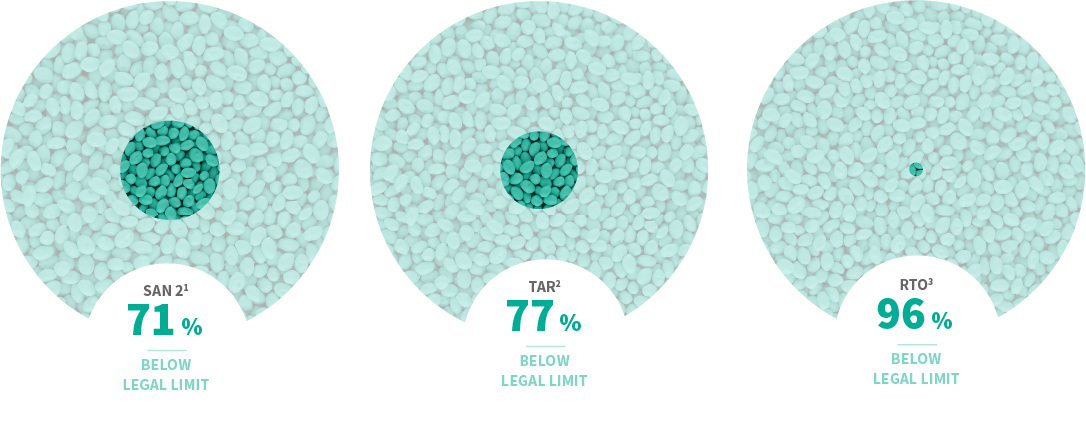

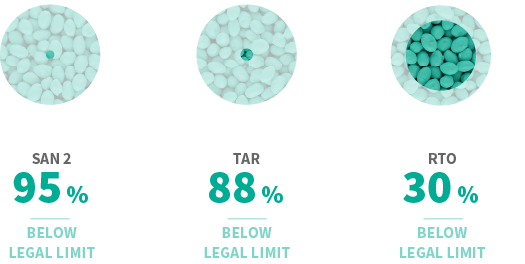

Contaminating atmospheric emissions of nitrogen oxide and carbon monoxide have hazardous consequences on the health of people and the environment.

NOX EMISSIONS

ANNUAL AVERAGE PER SOURCE FOR EACH PLANT (mg/Nm3)

LEGAL LIMIT

EMISSIONS IN 2020

1. Styrene copolymer and acrylonitrile production plant.

2. Waste gas treatment plant.

3. Thermal Oxidation Gas Treatment plant.

CO EMISSIONS

ANNUAL AVERAGE PER SOURCE BY PLANT (mg/Nm3)

Our emission levels of nitrogen oxide and carbon monoxide are much lower than current regulations permit.

textos.2022_enviroment_83

We are gradually shifting from linear collection and treatment management by an authorised facility to management with a circular economy perspective, constantly searching for ways to recuperate and revalue our own waste

We strictly monitor the proper and improper management of all our waste, identifying aspects we can improve such as labeling, packaging, location or warehouse deliveries.

4.117 t

TOTAL GENERATED WASTE

44,9 %

VARIATION 2020-2021

3,51 %

TONNES OF TOTAL WASTE PER TONNE PRODUCED

3,51 %

VARIATION 2020-2021

textos.2022_enviroment_91

ABS production requires the use of dangerous chemical products and creates highly hazardous waste, which, if poorly managed, can pose serious health risks to people and cause environmental damage. Our protocols for monitoring and managing these products are stringent and comprehensive.

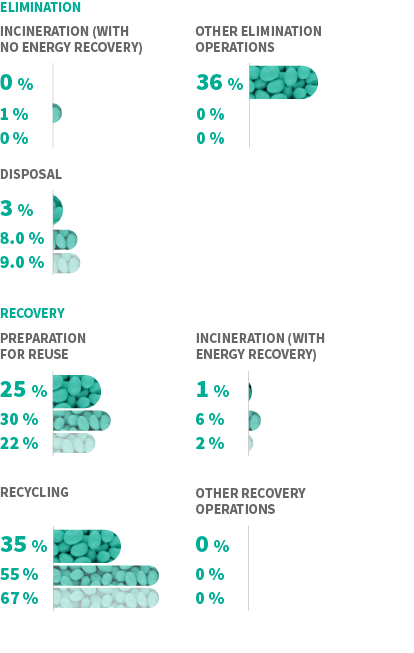

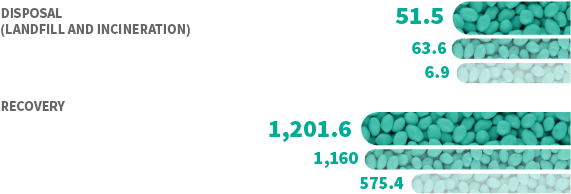

MAIN MANAGEMENT CHANNELS

(MANAGED TONNE PER CHANNEL/TONNE PRODUCED)

2020

VARIATION 2019-2020

textos.2021_enviroment_96-1

We've maintained our downward trend in waste generation and have managed a 91 % reduction.

2020

VARIATION 2019-2020

textos.2021_enviroment_96-1

textos.2022_enviroment_10

textos.2022_enviroment_11

textos.2022_enviroment_12

textos.2022_enviroment_13

Our water footprint

In the current context of climate change, predictions are that the Mediterranean coast will be one of the most affected areas. Water will become a scarce and precious good which will need to be distributed according to its different uses: domestic, agricultural and industrial.

We work to improve our efficiency in the use of this resource and to reduce the vulnerability of water drainage basins due to fresh water depletion. Our sustainability strategy 2030 sets the ambitious goal of reducing water consumption by 15% in comparison with 2017.

At ELIX we use closed circuit refrigeration water -- thus, there is zero consumption.

WATER CONSUMPTION

2021

VARIATION 2020-2021

116.516

TOTAL INDUSTRIAL WATER (m3)

-7,4 %

Water use efficiency:

0,99

WATER CONSUMPTION RELATIVE TO PRODUCTION (m3 /t ABS produced)

-20,2%

58,6 %

INDUSTRIAL WATER CONSUMPTION WITH RESPECT TO BASE YEAR 2013

textos.2022_enviroment_10

textos.2022_enviroment_14

textos.2022_enviroment_15

textos.2022_enviroment_16

NEED MORE INFORMATION?

DOWNLOAD THE 2024 SUSTAINABILITY REPORT